No products in the basket.

Order Online For Next Day Delivery

| Name | Price | Buy |

|---|---|---|

| 150 x 200 High Barrier Shrink Bags (Qty x2000) | £105.87 +VAT | |

| 200 x 300 High Barrier Shrink Bags (Qty x2000) | £153.03 +VAT | |

| 260 x 550 High Barrier Shrink Bags (Qty x500) | £79.74 +VAT | |

| 300 x 350 High Barrier Shrink Bags (Qty x1000) | £121.36 +VAT | |

| 300 x 400 High Barrier Shrink Bags (Qty x1000) | £136.26 +VAT | |

| 350 x 450 High Barrier Shrink Bags (Qty x500) | £80.61 +VAT | |

| 400 x 500 High Barrier Shrink Bags (Qty x500) | £102.51 +VAT | |

| 450 x 650 High Barrier Shrink Bags (Qty x500) | £151.67 +VAT |

Shrink Bags

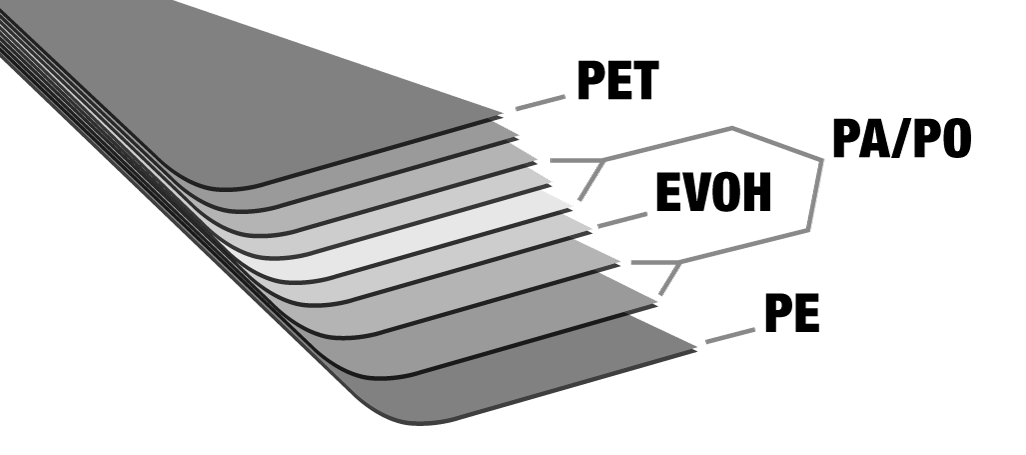

Our shrink bags use a 9-layer structure, therefore able to protect the EVOH layer with other useful layers that protect the EVOH gas barrier layer from moisture.

The 9-layer EVOH-structure provides the ultimate oxygen barrier even under extremely humid conditions from within or outside the package.

Shrink Bags with 9-Layer Technology

Our barrier shrink bags have a 9-layer structure providing a superior barrier against gases, water vapour and UV rays. Different compounds and raw materials have their own unique barrier qualities, and the right combination will ensure optimal protection for packaged goods.

Our shrink bags use a combination of market-leading films to provide a superior barrier, shrink, mechanical and visual properties. With a 9-layer structure, our shrink bags use materials not commonly found in high barrier structures (including PET for overlap sealing, printability, gloss and moisture protection), and use multiple layers of highly important materials (including PA for puncture resistance and PO for high shrink). Below includes the benefits and materials used in our 9-layer structure.

Material Barrier Properties (EVOH)

EVOH is an Ethylene-Vinyl Alcohol Copolymer mainly composed of carbon, oxygen and hydrogen. An environmentally friendly substance, EVOH is used as a high barrier resin. With its sophisticated molecular crystalline structure, EVOH is an extreme barrier against oxygen and other gasses. EVOH resins have a 10.000 times greater gas barrier than standard LDPE films.

When used in a multiple-layer structure, EVOH allows for the longest shelf life of meats and cheese due to almost completely eliminating oxygen permeability.

- Advanced Gas and Water Vapor Barrier

- Superior Shrink Rate (up to 50%)

- Overlap Sealing Capability

- Excellent Transparency and Gloss

- UV Light Resistant

- High Puncture Resistance

- Great Sealing Properties

Typical Usage and Applications

- – Fresh and Processed Meats

- – Packaging of large pieces of meat for transport/export

- – Block Cheeses

- – Block Hams

- – Sausages, Salami and Cold Cuts

- – Semi-finished products

EVOH Advantages

- – A sophisticated barrier against oxygen, nitrogen, carbon dioxide and helium, EVOH extends the shelf life of food products and protects their nutrients against bacteria.

- – Packaged products stay fresh through the supply chain, even when stored for extended periods of time. EVOH helps protect the taste, scent, color and freshness of a product.

- – Excellent transparency: EVOH helps create a clear packaging experience for the consumer.

- – EVOH is also recyclable and environmentally safe.

Technical Specifications

Coextruded shrink bag with high barrier properties for ripening and transport packaging of fresh meat, processed meat and non-gassy to low-gassy cheese types.

| Properties | Unit | Method | Conditions | Value |

|---|---|---|---|---|

| GENERAL DATA | ||||

| Total | Thickness | um | DIN 53 370 | 48 ± 10% |

| Shrinkage | ||||

| MD /TD | % | DIN EN ISO 2286-2 | Waterbath 75ºC | 20 / 25 |

| MD /TD | % | DIN EN ISO 2286-2 | Waterbath 85ºC | 33 / 40 |

| MD /TD | % | DIN EN ISO 2286-2 | Waterbath 95ºC | 47 / 50 |

| PERMEABILITY | ||||

| Vapour (Water) | g/m2d | DIN 53 122 | 23ºC / 50% r.h | <1 |

| Oxygen | cm3/m2dbar | DIN 53 380 | 23ºC / 0% r.h | 8 - 13 |

| Carbon Dioxide | cm3/m2dbar | DIN 53 380 | 23ºC / 0% r.h | 30 - 45 |

| MECHANICAL PROPERTIES | ||||

| Deterioration | ||||

| Force | N | DIN EN 14477 | 23ºC / 50% r.h | 6,9 |

| Work | mJ | DIN EN 14477 | 23ºC / 0% r.h | 9,1 |

| Deformation | mm | DIN EN 14477 | 23ºC / 0% r.h | 3,0 |

| APPLICATION DETAILS | ||||

| Shrink bags can be processed on all state-of-the-art sealing, clipping and shrinking equipment. | ||||

| (All values given in this datasheet are approximate and given to our best knowledge and therefore cannot be taken as guaranteed. Due to the manifold applications and processing possibilities, which are beyond our control, we recommend testing under real production conditions. Qualification test and the application release of the bags are incumbent upon the user. Data changes subject to technical progress.) | ||||